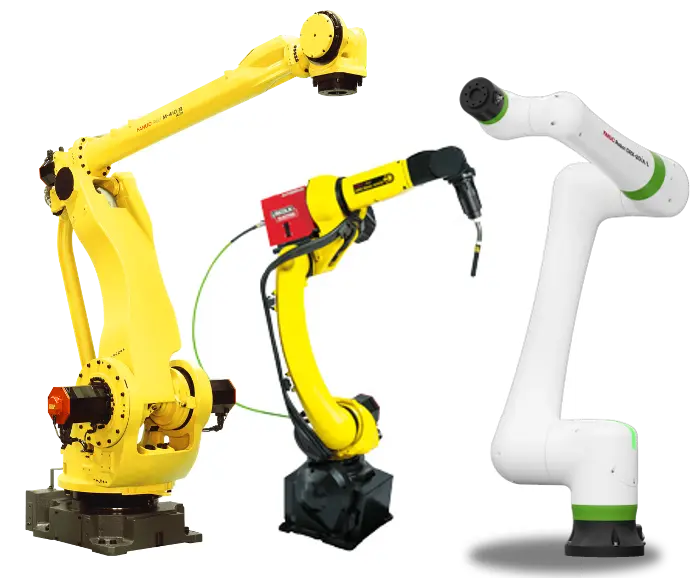

TRQ - Tending Robot Celles

DMQ offers complete Machine Tending Cells solutions and if you’re not sure where to start, DMQ automation experts are available to assist with scoping and building any machine tending automation project.

Flexible Robot Cells for any size machine shops.

The TRQ - series are simple, reliable and cost-effective is perfect for Machine Tending –operations where the robot pick objects from a pile, bin, or conveyor and placing them into a machine. When the machine’s operation is finished, the robot removes the finished parts.

Some of these Machine Tending jobs could be:

- CNC Machines

- Stamping Presses

- Press Brakes

- Plastics and Injection Molding

- Manually loading and unloading parts or components

These machines/processes normally requiring an operation to wait around and replace a part every minute or so, which is not good business –by assigning these tasks to a cobot your operator can focus on other and more delicate tasks.

Key Benefits

- REDUCED COSTS - Robotic automation can help reduce the overall cost of manufacturing. It allows you to make the best use of your labor costs by removing non-value-added tasks from the hands of human workers.

- INCREASED CONSISTENCY - While productivity is often the headline benefit of robotics, consistency is usually a more useful benefit. The improved consistency of your robotic CNC machine can have a significant impact over time, affecting many aspects of your production process

- ENHANCED ACCURACY - With manual machine tending, there is always a possibility that an operator will place a workpiece in the machine in slightly the wrong position or orientation, ruining that piece. A robot always places it in exactly the right position every time.

- DECREASED DOWNTIME - By tending your machine with a robot, that machine spends less time doing nothing. This helps to improve the Overall Equipment Effectiveness of that CNC machine.

- INCREASED FLEXIBILITY – It is quick and easyto reprogramtherobot to handle a new product and it can easily be relocated within the production facility or moved from one machine to another as needed.

- IMPROVED QUALITY CONTROL - Automating your CNC process with a robot also makes quality control simpler and quicker. By reducing human error, you gain better overall control of your product quality.

- IMPROVED SAFETY - Using a robot to automate your CNC machining process can help to create a safer working environment by eliminating the need for human workers to be close to moving machinery.

FEATURES

- Standard Cell with a robot selected according to your needs, such as speed, reach, and payload to optimize your cycle rates and costs.

- Compact and portable - Easy to move from one machine to another.

- Easy installation and setup (2 hours)

- Programminginterface with simple drag and drop functionality on a tablet teach pendant.

- High safety standards.

OPTIONS

- IRVision guidance system increased speed and efficiency

- Robotic systems can be programmed to handle various machines.

- Table and Shelfing system –for increased capacity.

- Multiple feeding options -Conveyor, Angle feeder, Carousel, Grid

- Different tools to accommodate your product’s requirements.

- Stainless steel components for food industry requirements.