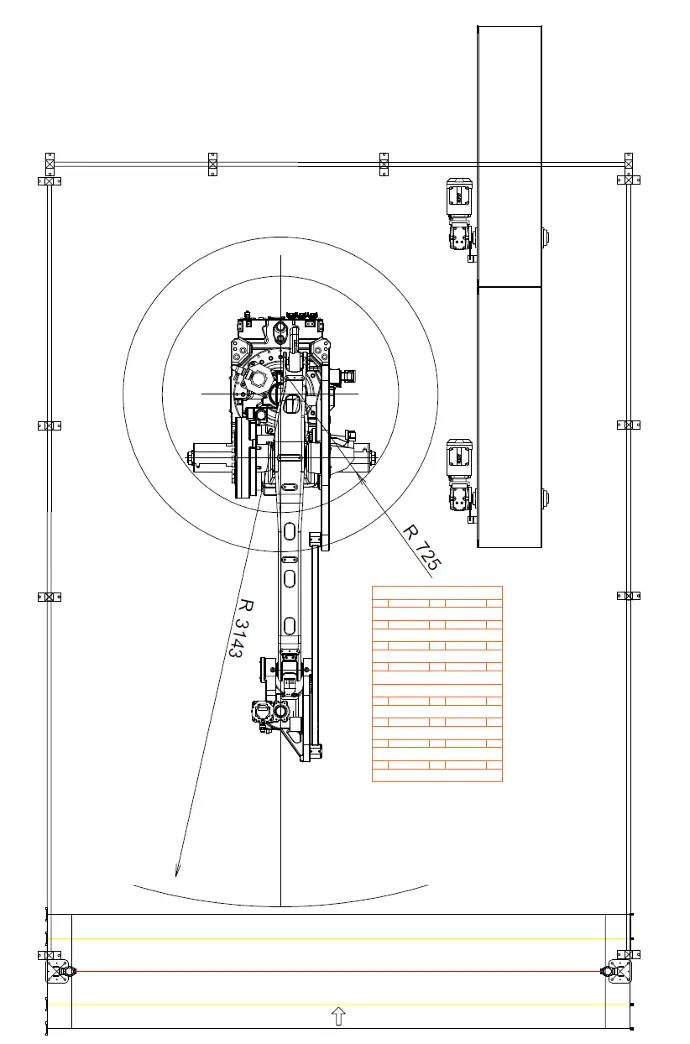

RPQ - SEMI-AUTOMATED CONFIGURATION

Affordable, simple, and reliable palletizing with a small footprint.

- The RPQ-Series stands out as a budget-friendly and simple palletizing robot, and an ideal choice when getting started with robotics, utilizing manual pallet placement directly on the floor.

- Simple, flexible, and easy to maintain, these robotic palletizers can handle any types of containers of various shapes and sizes with speed and reliability.

- Multiple patterns at lower speed

- The RPQ-Series builds pallet loads directly on the floor from a single production line. When completed, the lift operator enters the cell to swop the full pallet with an empty one.

- The modular design of our RPQ-2100 series enables straightforward integration.

FEATURES

- Compact and modular layout for easy integration.

- Flexible and very reliable robot -selected according to your needs, such as speed, reach, and payload to optimize your cycle rates and costs.

- Safety fences and light curtains to keep your employees safe.

- Built with high-quality components for low-cost maintenance.

- Quick installation and commissioning.

OPTIONS

- Multiple tools can be fitted to accommodate your product’s requirements.

- Sheet dispenser and sheet handling.

- Additional pallet stacking positions can be added, reducing the operator's time spent in the cell.

- Stainless steel components for food industry requirements.

- Standard motorized conveyors.

- Preparation conveyorwhere the units are gathered –allow the robot to lift multiple units per cycle, thus increasing the capacity accordingly.

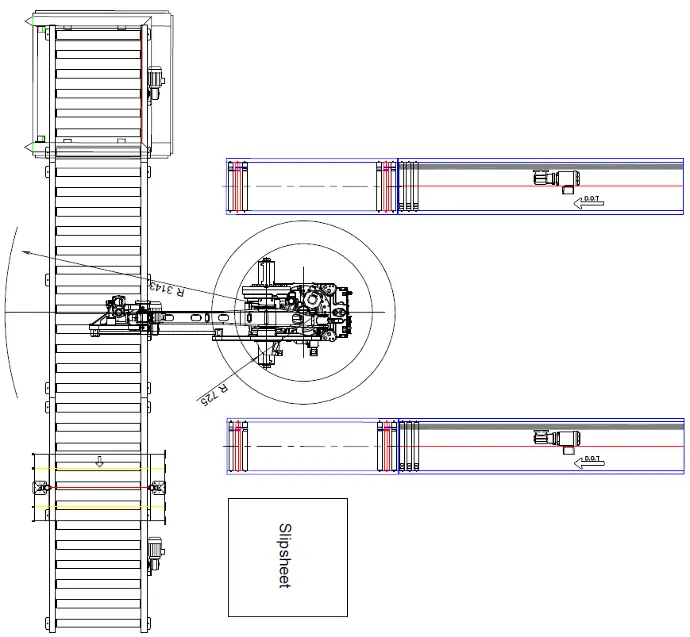

FULLY AUTOMATED CONFIGURATION

Fully automated configuration - flexible and reliable palletizing

- The RPQ Series is well-suited for facilities experiencing moderate production volumes. This level of automation significantly reducing the operator’s time spent in the cell, leaving the operator to complete other tasks.

- Utilizing the robot's flexibility and adaptability, the design efficiently positions pallets, slip sheets, and units for stacking, eliminating the necessity for extra equipment, thus optimizing floor space utilization.

- The RPQ- Series can also be configured as a fully automated solution but still flexible and easy to maintain, while handling any types of containers of various shapes and sizes with speed and reliability.

FEATURES

- ✓ UP to 1200 picks per hour – dependent on type of product, patterns

- ✓ Automatic handling of units, sheets and pallets.

- Compact and modular layout for easy integration.

- ✓ Flexible and very reliable robot - selected according to your needs.

- Safety fences and light curtains to keep your employees safe.

- ✓ Built with high-quality components for low-cost maintenance.

OPTIONS

- Multiple tools can be fitted to accommodate your product’s requirements

- ✓ Additional standard motorized conveyors.

- ✓ Separation conveyor.

- ✓ Rejection conveyor for non-compliant units.

- ✓ Multiple infeeds and outfeeds available.

- ✓ Stainless steel components.

- ✓ IRVision 3D guidance system for increased speed and efficiency